Due to different automotive components’ characters, their laser process can be divided into 2D and 3D laser processing.

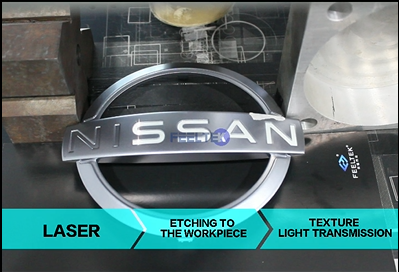

The work logic is through laser etching to the workpiece, to achieve texture, light transmission, and other effects.

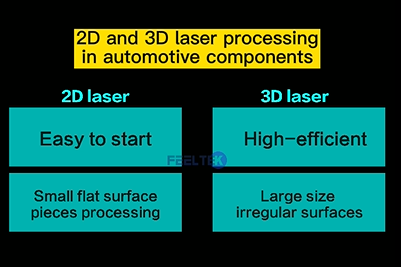

In the early years, a 2D scan head with an f-theta lens, can work on flat small pieces such as key buttons, and dashboards,such job is easy and the calibration work is fast.

In recent years, under the trend of consumption upgrading, comfort has become the first element of automotive selection, and the automotive accessories are also pursuing more and more personalized towards large size and special curved surface development, so the 3D laser processing began to be applicated in the manufacturing of automotive accessories.

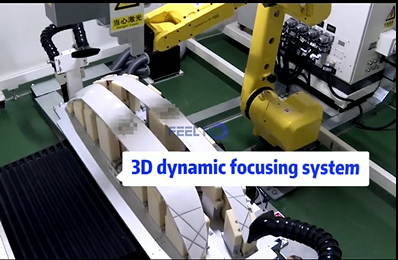

3D laser process is through the use of laser and 3D dynamic focusing system technology,in the processing of large size and irregular surfaces, the Z axis of 3D dynamic focusing system can be flexible moved back and forward to compensate the focal length, it not limited by the f-theta lens.It has different aperture sizes and work fields for choice to achieve one-time processing on large pieces and irregular surfaces.

The 3D laser processing has been widely applicated in Lights, bumpers, inside and outside large decorative panels, central control panels, hub etc.

Let’s summarize the difference between 2D and 3D laser processing in automotive components.

Post time: Oct-12-2022