Ukuwelda ngelaser yenye yezinto ezibalulekileyo zokusetyenzwa kweetekhnoloji ukusukela ngeminyaka yoo-1970.

Ngokukhula okuqhubekayo kobuchwepheshe kunye nokuhla kwexabiso lezixhobo ze-laser, izikimu ze-laser welding zisetyenziswe ngokubanzi kumashishini ahlukeneyo.

Iinkampani zemizi-mveliso ezifana ne-HIGHYAG, i-TRUMPF zibeke iinzame kuphando kunye nophuhliso lwe-laser scanning welding technology kunye nezixhobo ngokweemfuno zenkqubo, kwaye ziphumelele izisombululo zezityalo ze-laser zokuskena.

Xa kuthelekiswa netekhnoloji ye-welding yemveli, iingenelo ezichaneke ngakumbi nezisebenzayo ze-laser scanning welding ziye zaqinisekiswa ngokupheleleyo.

Okwangoku, iingcali zoshishino ziyaqhubeka nokuphucula iteknoloji yesicelo se-laser welding, ukukhuthaza ukusetyenziswa kwale nkqubo kumashishini amaninzi.

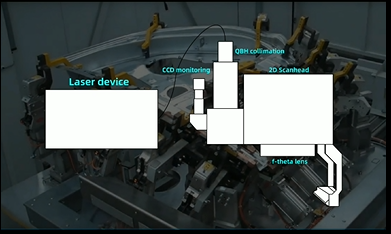

Isethi eqhelekileyo ye-laser scanning welding systems ineemodyuli ezingundoqo ezintlanu: i-laser device, i-QBH collimation, i-CCD yokubeka iliso, intloko yokuskena, kunye ne-f-theta lens.

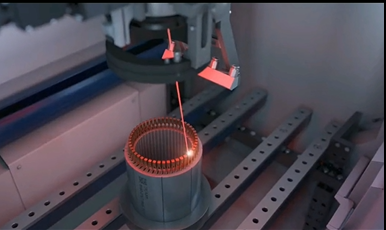

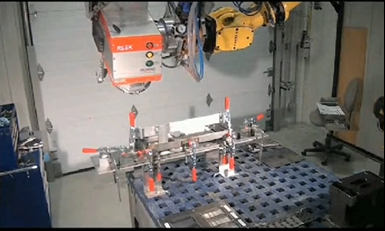

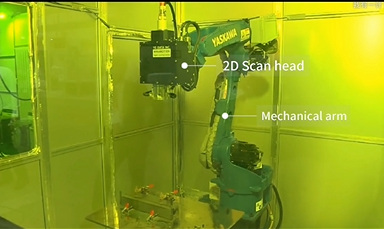

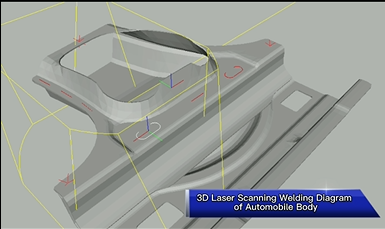

Kwinqanaba lokuqala, isisombululo se-laser welding ikakhulu sisebenzisa intloko ye-2D scan edityaniswe nengalo yomatshini, usebenzisa intshukumo eguquguqukayo yengalo yomatshini enedigri ezininzi zenkululeko yokuqonda yonke inqaku le-welding kwindawo yomatshini kwi-fixed focal length. Esi sisombululo sisetyenziswe ngokubanzi kwimveliso eninzi yemizimba yeemoto kunye neendawo ezisecaleni ukuze kuphunyezwe ukukhanya kwemoto.

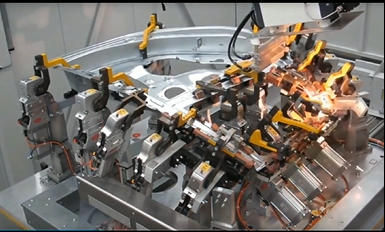

Ngophuculo oluqhubekayo lokuzenzekelayo, ukusetyenziswa kwetekhnoloji ye-laser ye-welding welding iba banzi ngakumbi kushishino.Ngokomzekelo, kushishino lwezithuthi zamandla olutsha olukhula ngokukhawuleza, uyilo olutsha lwezahlulo zemoto, iibhetri zamandla, kunye namanye amacandelo ukusetyenzwa. umngeni omkhulu kwisisombululo esele sikhona kwaye ubeka phambili iimfuno eziphezulu ze-frequency-stop-stop frequency kunye nokubeka ukuchaneka kwengalo yomatshini kwi-welding.

Ukufikelela njani kwisantya esiphezulu se-laser ukuwelda kwindawo enkulu entsonkothileyo yomphezulu? Ukufikelela njani kubude obukhawulezayo bokujolisa ukulungelelanisa phantsi kobude obuhlukeneyo bomsebenzi?

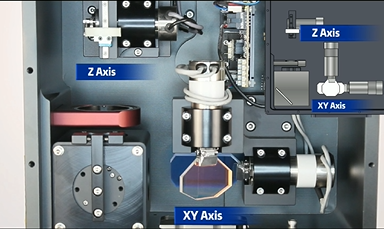

Sinokuyiphucula intloko ye-2D yokuskena kwisixhobo se-laser ye-welding welding system ukuya kwi-3D eguquguqukayo ekugxilwe kuyo, i-Z-direction dynamic axis ye-dynamic focus system inokusebenzisana ngokubambisana ne-XY axis.Njengoko umgama wokusebenza utshintsha ngexesha lenkqubo ye-welding, i-axis ye-Z-direction dynamic ihamba ngasemva naphambili ukwenza imbuyekezo ekugxilwe kuyo, inokuqinisekisa ukuhambelana kogxininiso lwendawo kuyo yonke inkqubo yokusebenza, kwaye iqonde ukuwelda okudityanisiweyo kwesantya esiphezulu. uluhlu olukhulu lweendawo ezintsonkothileyo zomhlaba, kwaye unciphise kakhulu ixesha lokumisa ingalo yerobhothi kunye nexesha lenyathelo kwimveliso.

Kwangaxeshanye, ukunciphisa impazamo yokubeka ebangelwa kukuqala rhoqo kunye nokuma kwengalo yomatshini, uhlengahlengiso olukhawulezayo lokugxila kobude obahlukeneyo lunokuphunyezwa ngolungelelwaniso olupheleleyo phakathi kwe-axis ye-Z-direction dynamic axis kunye ne-XY axis ye-dynamic. inkqubo yokugxila, kunye nokugqiba umsebenzi welding.Ukusebenza kakuhle kuphuculwe kakhulu, kulula ukufezekisa umgca wemveliso ozenzekelayo.

Yazi ngakumbi kwijelo le-FEELTEK TECHNOLOGY

Ixesha lokuposa: Sep-23-2022