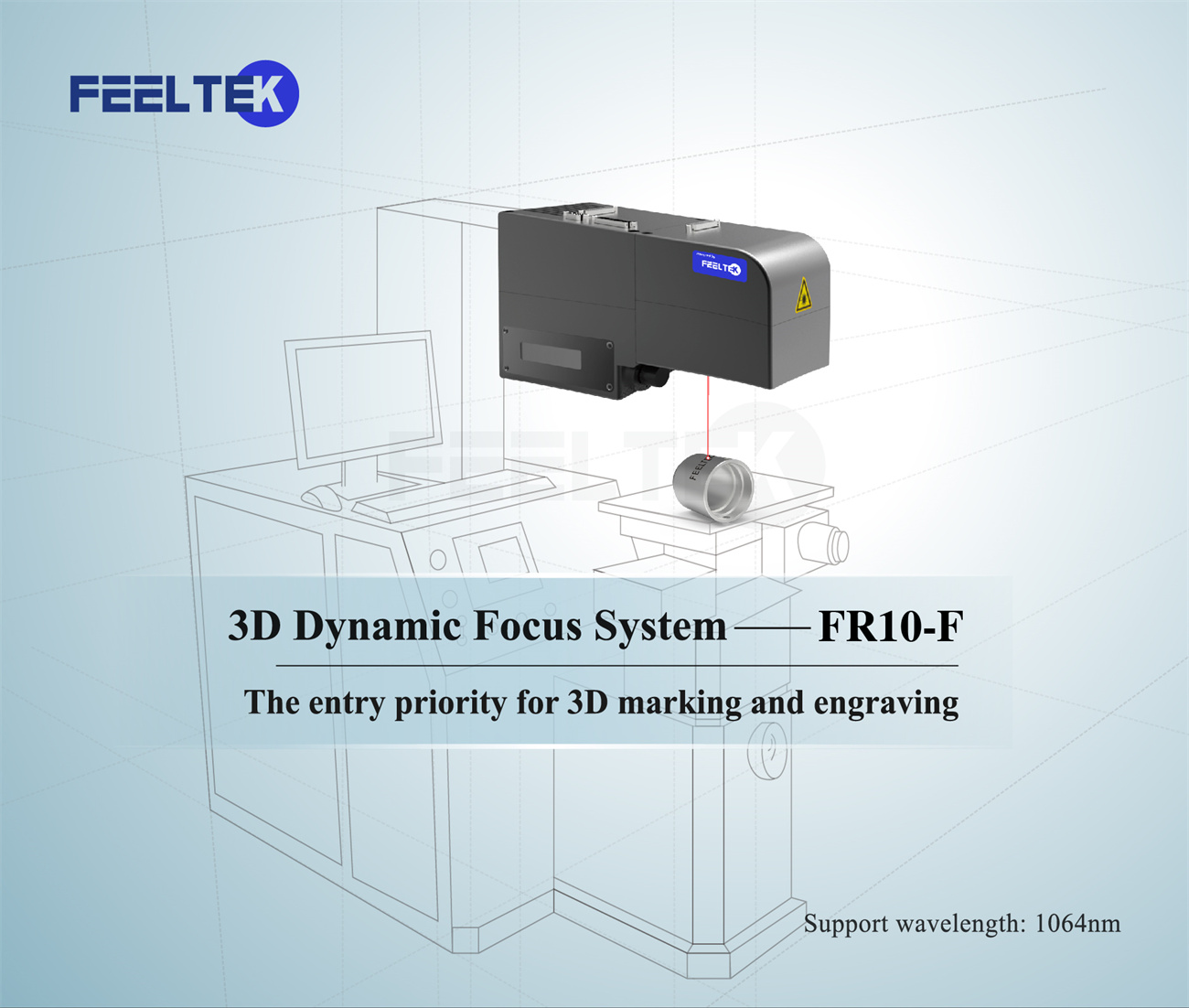

3D Dynamic Focus System一FR10-F

Applications

Multiple applicable environments

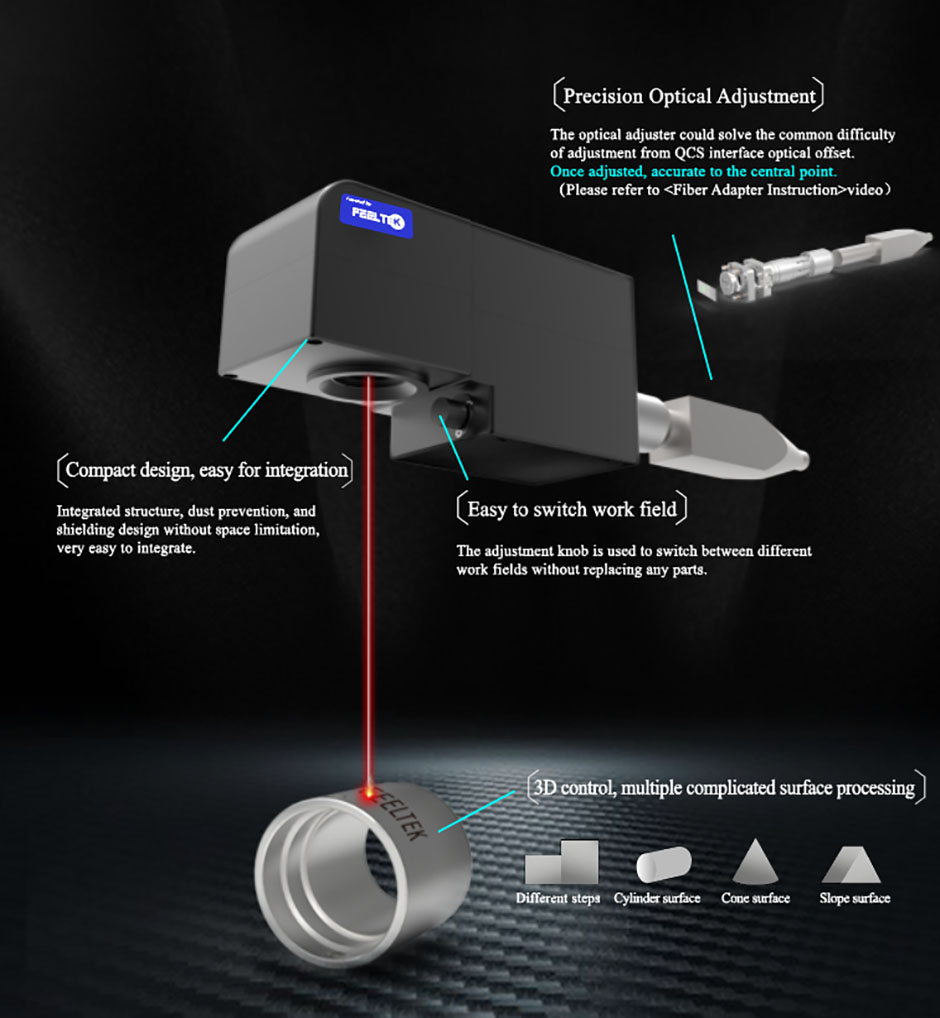

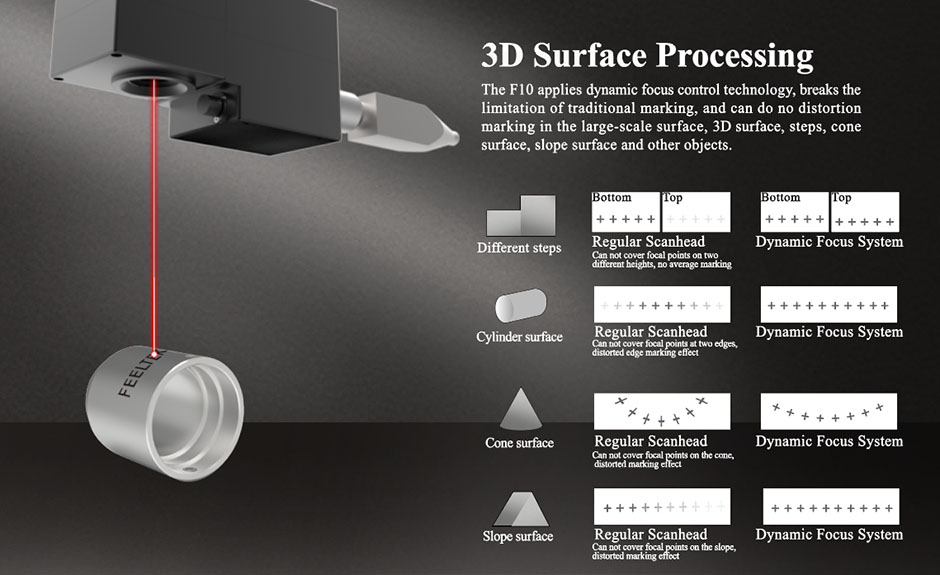

Without the extra moving platform, the dynamic focus system can achieve accurate 3D marking, engraving and other laser applications.

One-time 3D marking without chromatic difference

3D surface tracking code marking

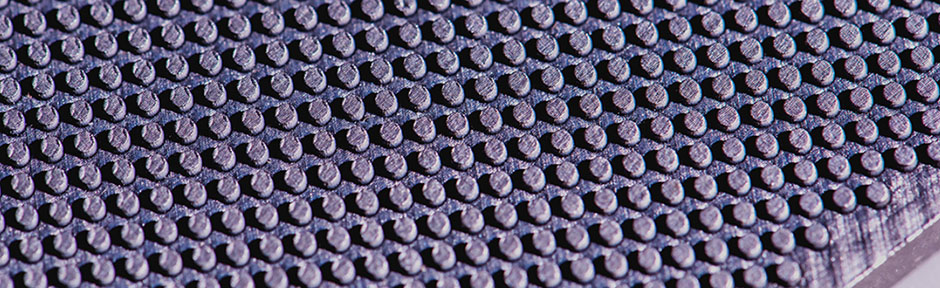

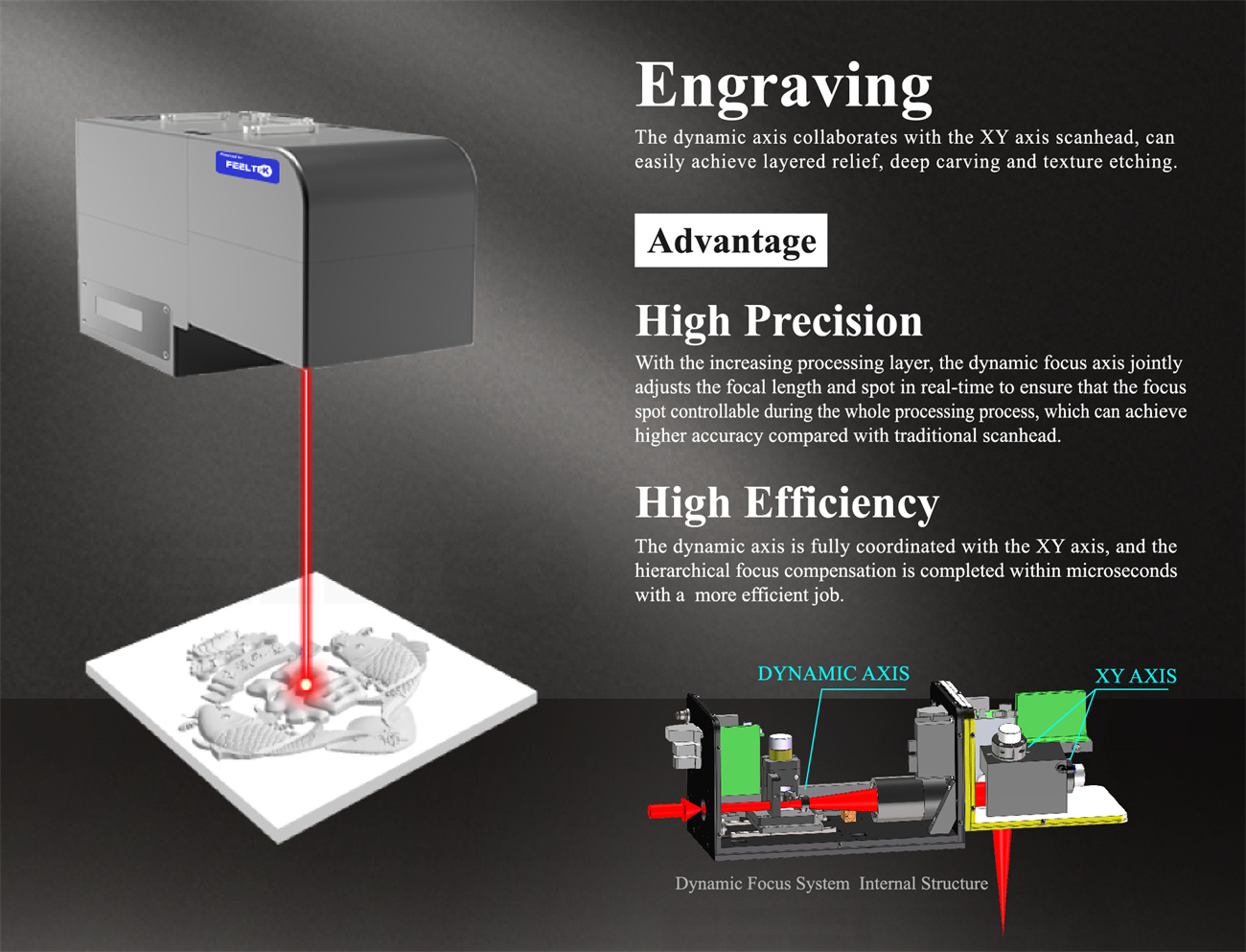

3D surface engraving

Male&Female mould engraving

Special material deep engraving (material: SIC)

Application Highlight

Laser device types for engraving work

We recommend a pulse laser under 100 watts to process the engraving. Although high-power laser can have a deeper single-layer etching, however, it will lead to material slag and affect the engraving accuracy.

How could laser engraving be more precise?

The correction precision of the dynamic focus system has signification impact on the engraving effect.

We open CCD automatic correction platform, scanner correction tools options for users if needed.

Additionally, the FEELTEK instruction video will also share how to achieve precision correction.

Materials for engraving

Suitable material for F10: brass, carbon steel, mold steel, stainless steel, SIC etc.

FEELTEK can share the application guidance parameters for the above materials.

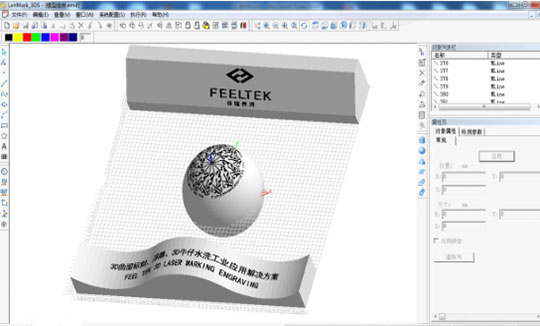

User-friendly Dynamic Focus System Software

-- LenMark_3DS

Easy operation

The self-developed LenMark software is specific for dynamic focus control. The 3D interface is easy to operate, can import 3D images directly, edit and map, quickly realize the 3D surface accurate processing control.

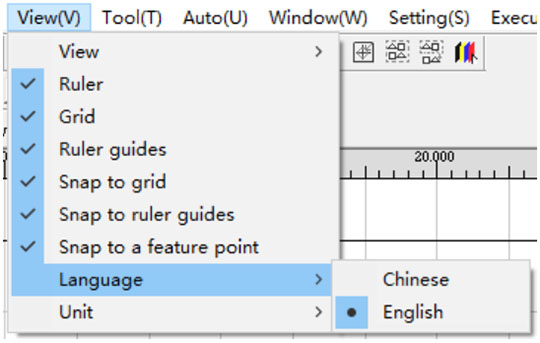

Language interface switching

Through the menu guidance, it can achieve the sofware interface switch in different languages without restarting the software.

Product Technical Information

Items

| Power Supply | Output Voltage(VDC) | 士15VDC |

| Current(A) | 10A | |

| Output Interface | xY2-100 Protocol | |

| Ambient Temperature ( ℃) | 25土10 | |

| Storage Temperature ( ℃) | -10~+60 | |

| Humidity | ≤75% non condensing | |

| Weight | 7kg | |

Specifications

| Product line | F10 / F10 Pro | |

| ptical pecifications |

Support wavelength | 1064mm |

| Aperture Size(mm) | 10 | |

| Input beam diameter(mm) | 8.5 | |

| Galvanometer Specifications |

Scan Angle(°) | ±10 |

| Repeatability(μrad) | 8 | |

| Max.Gain Drift(ppm/k) | 100 | |

| Max.Offset Drift(μrad/k) | 30 | |

| Long-term drift over 8h(mrad) | ≤0.3 | |

| Tracking Error(ms) | ≤0.13 | |

| Max.processing speed(charaters/s) | 600@100x100 | |

Note: Difference between Standard Version and Pro. Version: Higher galvo configuration for Pro. Version.

According to the test report, Pro. Version has better performance under long-term continuous work environment.

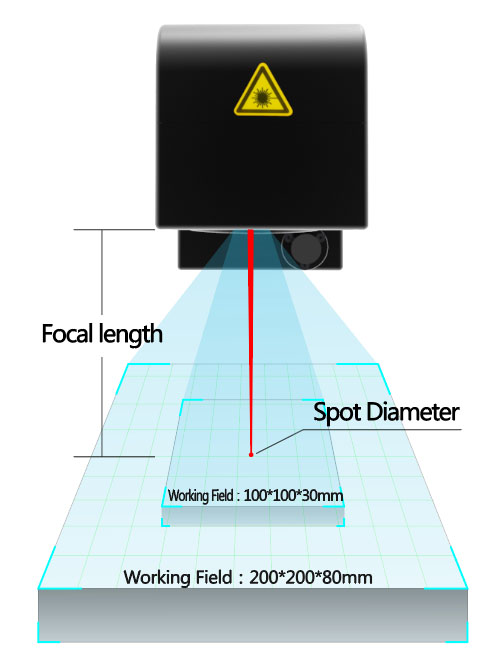

Working Field & Spot Diameter

|

Working Field(mm) | 100×100×15 | 200×200×80 |

| The Min.Spot Diameter@1/e2 (mm) | 0.025 | 0.0415 | |

| Focal length(mm) | 114 | 234 |

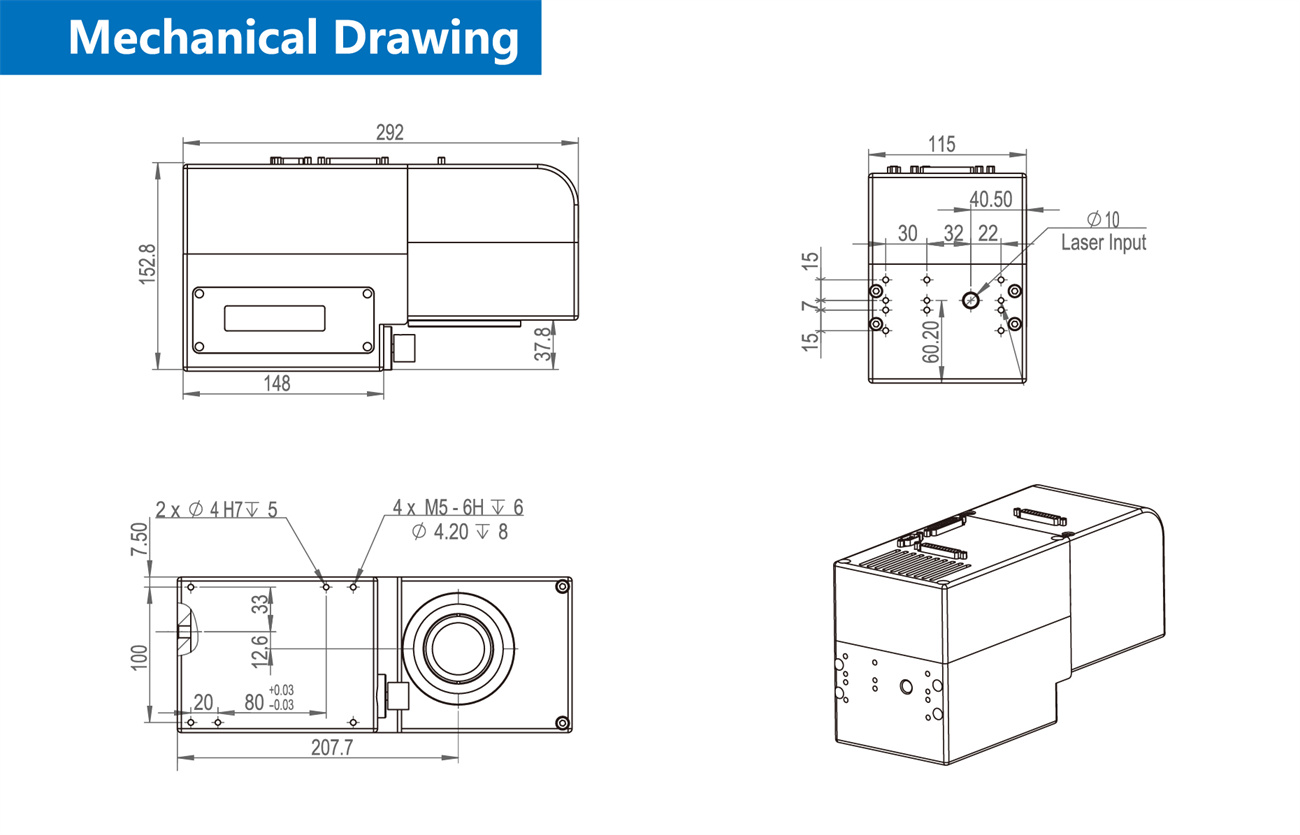

Mechanical Drawing