With the trend of industrial intelligence and precision processing, the demand for laser precision processing in precision 3C industry, machinery, new energy vehicles and other industries has developed rapidly, which has enabled the application of laser processing technology in the industrial field to be more comprehensively promoted.

Due to the inherent nonlinear characteristics between optics and scanners, the scanhead has graphic distortion during the scanning. As the “Inventing the 3D Dynamic Focus Technology”, FEELTEK has designed a new set of online compensation algorithms to eliminate optical distortion and other problems.

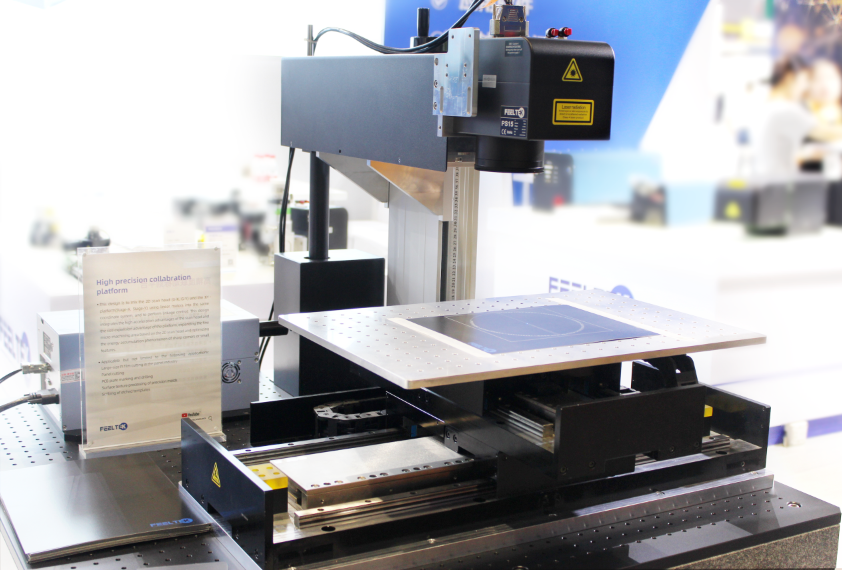

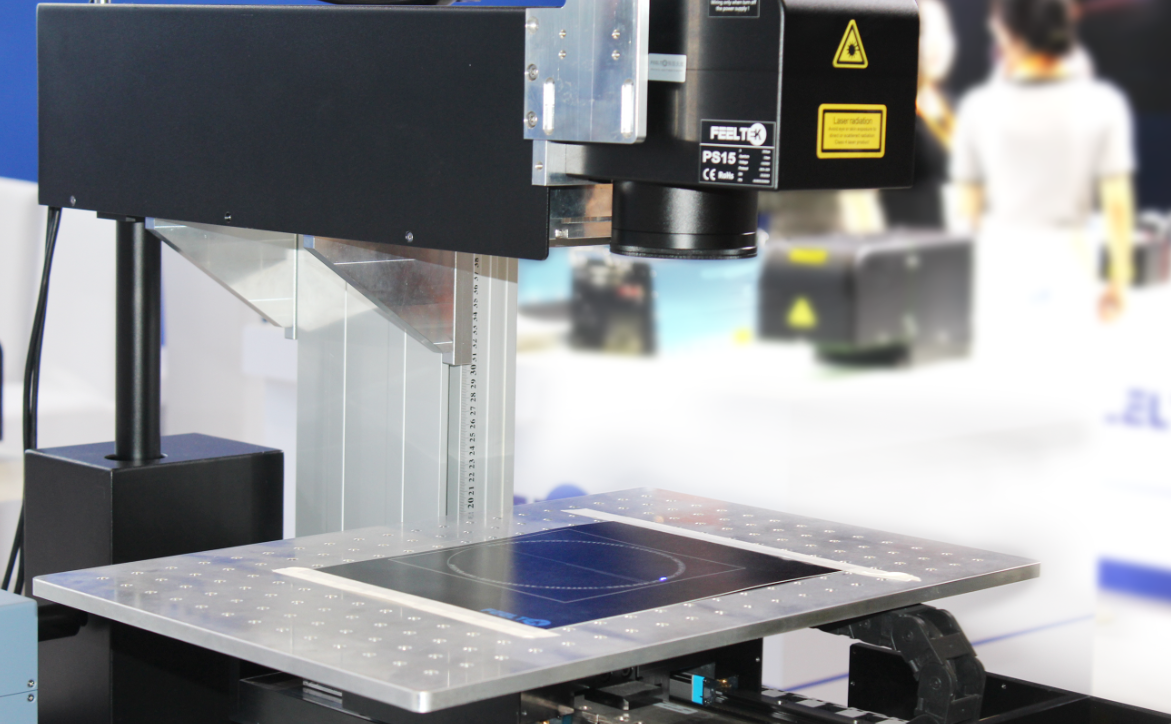

High-precision laser linkage platform

Scanhead platform linkage

This design integrates the high acceleration advantages of scanhead and the size expansion advantage of the platform. Which is to mix the 2D scanhead (G-X, G-Y) and the XY platform (Stage-X, Stage-Y) using linear motors into the same coordinate system, and to perform linkage control. This means the fine micro-machining area based on the 2D scanhead will be expanded. At the same time, the energy accumulation phenomenon of sharp corners or small features will be optimized. And the scars or errors caused by secondary processing at the same position will be reduced or eliminated, and the processing efficiency will be improved. In this way, the processing efficiency is improved, the cycle time is shortened, and the yield rate is significantly improved.

Linkage algorithm optimization

The scanhead moves quickly and the platform moves in a wide range. When the scanner and platform are linked, the action is decomposed into the movement of the scanhead + platform. This requires the fastest beat, taking into account both accuracy and speed. The frequency division control algorithm, also known as motion vector decomposition, is used to maximize the role of the scanhead, share the work of the platform, and minimize the workload of the platform; at the same time, the optimization algorithm enables the scanhead to play its role in the appropriate place.

PWM control

The PWM pulse is generated by the controller, and after passing through the servo amplifier, is directly used for the Motor’s current loop control. At the same time, the grating scale signal is directly fed back to the controller, thereby forming a fully closed-loop control. Gain higher control and real-time performance, and shorten the control cycle.

Application Fields

(this solution can be applied to but not limited to the following application fields)

Large-size PI film cutting, panel cutting, PCB plate making and drilling in the panel industry, surface texture processing of precision molds, fine scribing of etching templates, etc.

——————————————————————————————————

When lasers become an innovative tool, dynamic focusing systems with technological connotations are among the heroes. Teams and companies that specialize in developing dynamic focusing systems are given more expectations. Based on the strategy of The leader in industrial laser 3D dynamic focusing system, FEELTEK has deeply cultivated the application technology of dynamic focusing systems. It has successively launched a front-focus dynamic focus system, a rear-focus dynamic focus system, and a flexibly customizable dynamic focus unit DFM (Dynamic Focus Module).

In the future, FEELTEK will continue to strengthen collaboration with equipment integrators, take more actions to achieve complete implementation of processing technology and process verification of key indicators, and provide complete closed-loop equipment process solutions for more industry integrators.

Post time: Oct-07-2023