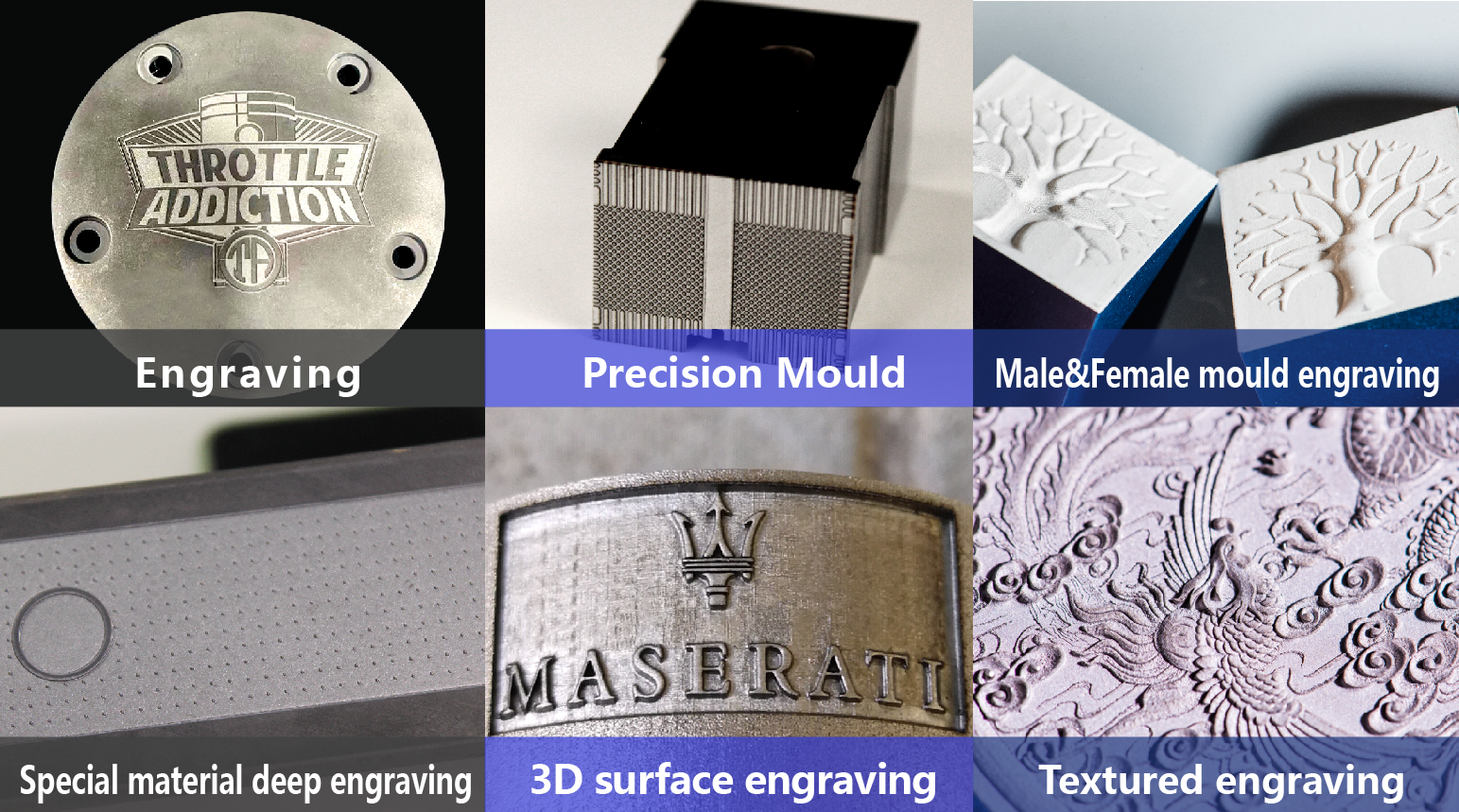

This is a coin mold used to stamp various commemorative coins. In the manufacturing of various types of molds, the samples we display use 3D laser precision engraving technology.

The principle is to focus the laser on the surface and remove material layer by layer to achieve a three-dimensional effect. Compared with CNC processing of small-sized micro-engraving, this process can produce finished products in one time, so it is favored for precision processing.

The size of this mold is 30mm, the height difference is 4dmm, and the engraving graphics are complex. In the laser engraving process, accuracy and efficiency are the most of users’ pursuit.

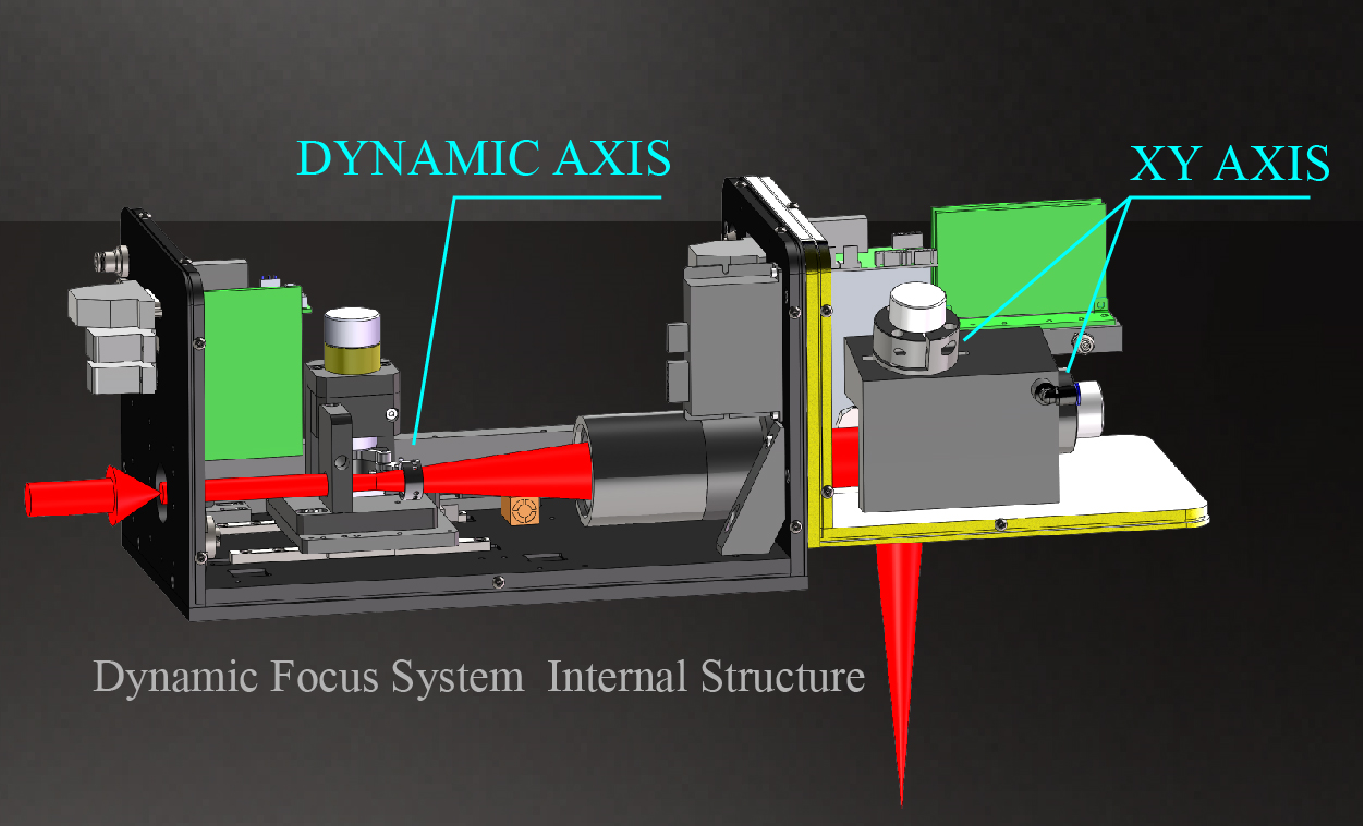

In the laboratory, FEELTEK use the dynamic focusing system FR10-F, combined with mopa laser or end pump 50W laser for engraving. First, import the model, texture, and slices into the LenMark software, and quickly generate the corresponding process parameters for each layer in the software, then use laser and 3D dynamic focusing system to engrave it layer by layer.

During the engraving process, as the number of processing layers’ increases, the dynamic axes coordinately adjust the focus to adjust the light spot in real time, it ensures that the focus spot is controllable by software during the entire processing process, and can achieve higher accuracy than traditional scanhead.

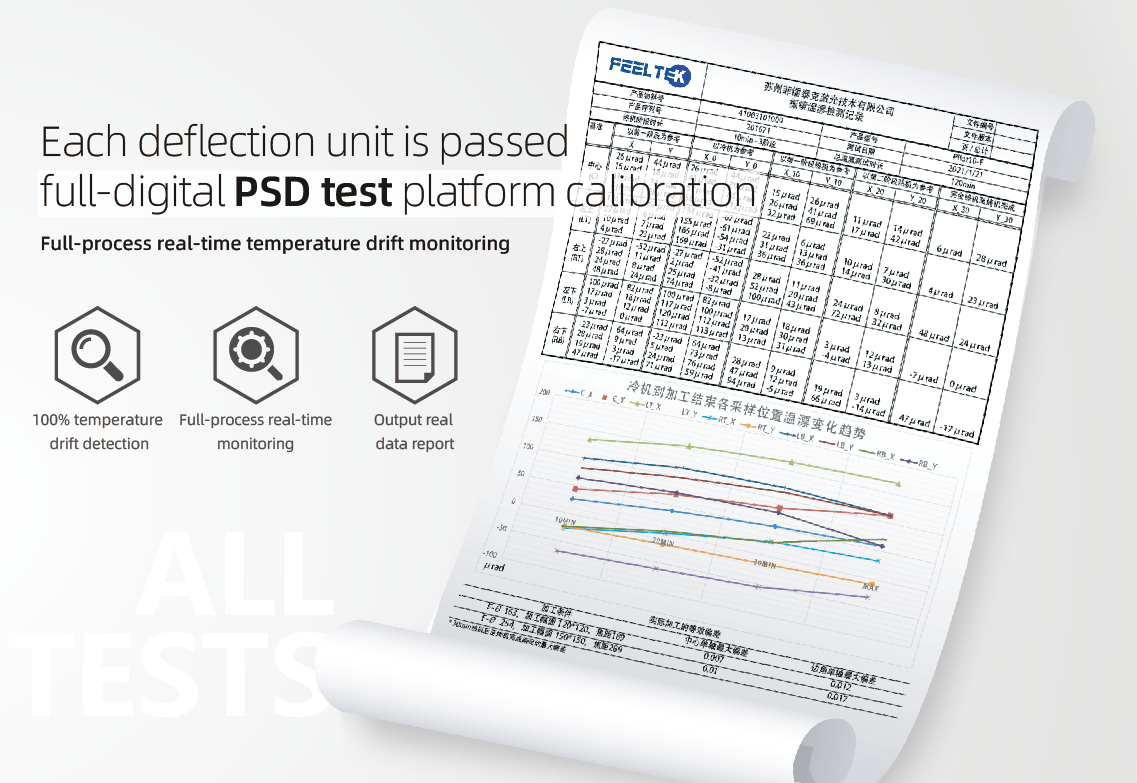

With the cooperation of dynamic axis and XY axis, hierarchical focus compensation is completed in microseconds with high efficiency. In order to ensure the positioning accuracy and temperature drift of the dynamic focusing system under long-time operation, each scanhead needs to be calibrated by a fully digital PSD temperature drift measurement platform. It works continuously for more than two hours on the four corners and center of the working area, and collect real-time data, and output the real temperature drift report.

In fact, FEELEK’s FR10-F dynamic focusing system can be freely switched within the working range of 100*100-200*200mm, focal depth 15-80mm, the smallest light spot can reach 0.025mm, which is widely used in the field of precision processing. Finally, let’s take a look at the engraving effect of this commemorative coin mold.

In addition, this technology is also widely used in different application, welcome to discuss more laser applications with us.

Post time: Nov-20-2023