Introduction

In recent years, laser cleaning has become one of the research hotspots in the field of industrial manufacturing. The emergence of laser cleaning technology is undoubtedly a revolution in cleaning technology. Laser cleaning technology makes full use of the advantages of high energy density, high precision, and efficient conduction of laser energy. Compared with traditional cleaning techniques, it has obvious advantages in terms of cleaning efficiency, cleaning accuracy, and cleaning location. It can effectively avoid environmental pollution caused by chemical corrosion cleaning techniques and does not damage the substrate and is expected to become the most promising green cleaning technology of the 21st century.

Principle

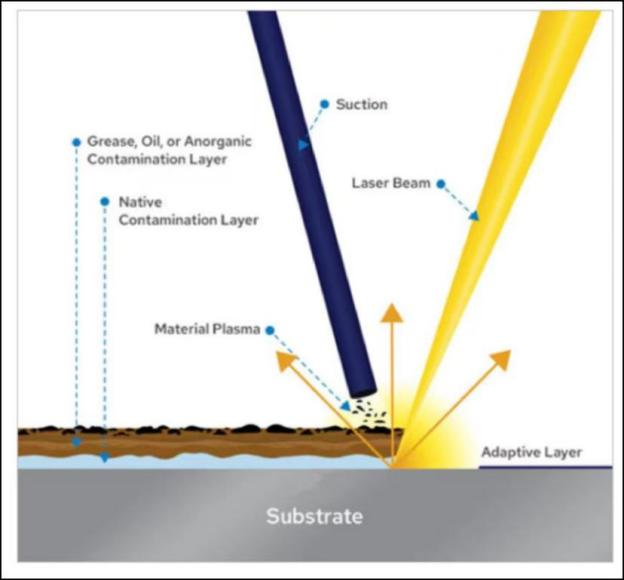

Laser cleaning is a process that utilizes the high energy density, direction controllability, and strong concentration capabilities of laser beams to remove contaminants from surfaces by breaking down the binding forces between the contaminants and the substrate or directly vaporizing the contaminants. The purpose of this process is to reduce the binding strength between contaminants and substrates and thereby achieve surface cleaning on workpieces. The laser cleaning process can be broadly divided into four stages: laser gasification decomposition, laser peeling, particle thermal expansion of contaminants, substrate surface vibration and contaminant detachment.

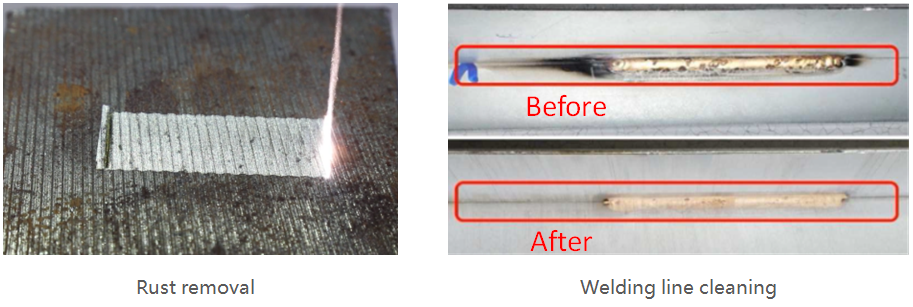

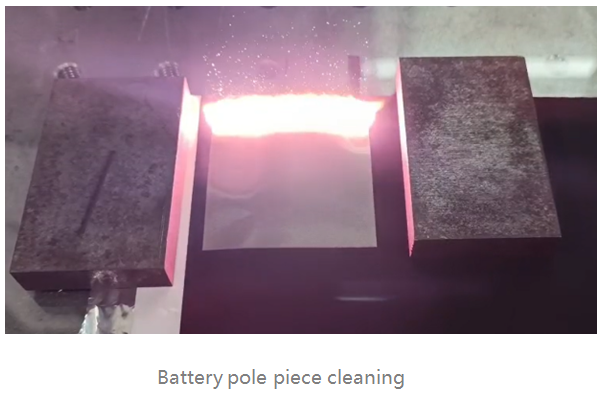

Application

Laser cleaning technology is a relatively advanced technology with broad research and application prospects in high-precision fields.

FEELTEK’s high-performance laser scanner have rapid scanning speed and high accuracy. Combined with our professional control software systems, we can meet various laser cleaning application requirements.

The near future will see substantial advancements in laser cleaning technology, which will give linked sectors a boost.

Post time: Aug-09-2023