Adding text, logos, or pictures to glass can be a challenging laser process due to its fragility. However, we understand the importance of achieving better engraving effects for personalized items.

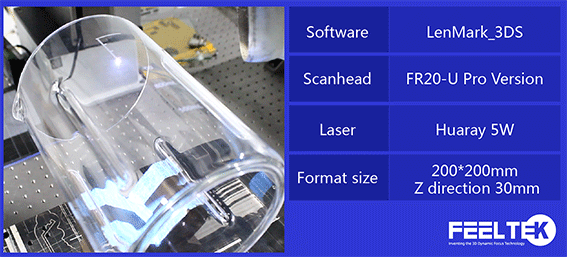

After interaction with the customer, FEELTEK engineers proposed a feasible solution that meets the above requirements:

Process Effects and Analysis:

1. During the actual adjusting process, the format selection should not be too large.

2. Use the projection function during the marking process. The projection function will change the size to a certain extent, but the visual quality will be much better.

3. To ensure optimal results, try to escalate the laser power to a range between 5W-8W since 3W power is insufficient in some cases.This increase in power will enable us to attain the desired effect on a wider range of glass materials. Additionally, the time required for the process will vary based on the specifications, with higher power resulting in faster completion.

4. When the 3D dynamic focusing system performs Z-direction correction on curved surfaces, it is recommended to use more layers to ensure the effect of curved surface marking.

5. Select the corresponding filling density according to the actual laser power. It is recommended that the filling density should not be too dense (and affect the efficiency and poor printing effect)

Post time: Apr-15-2024