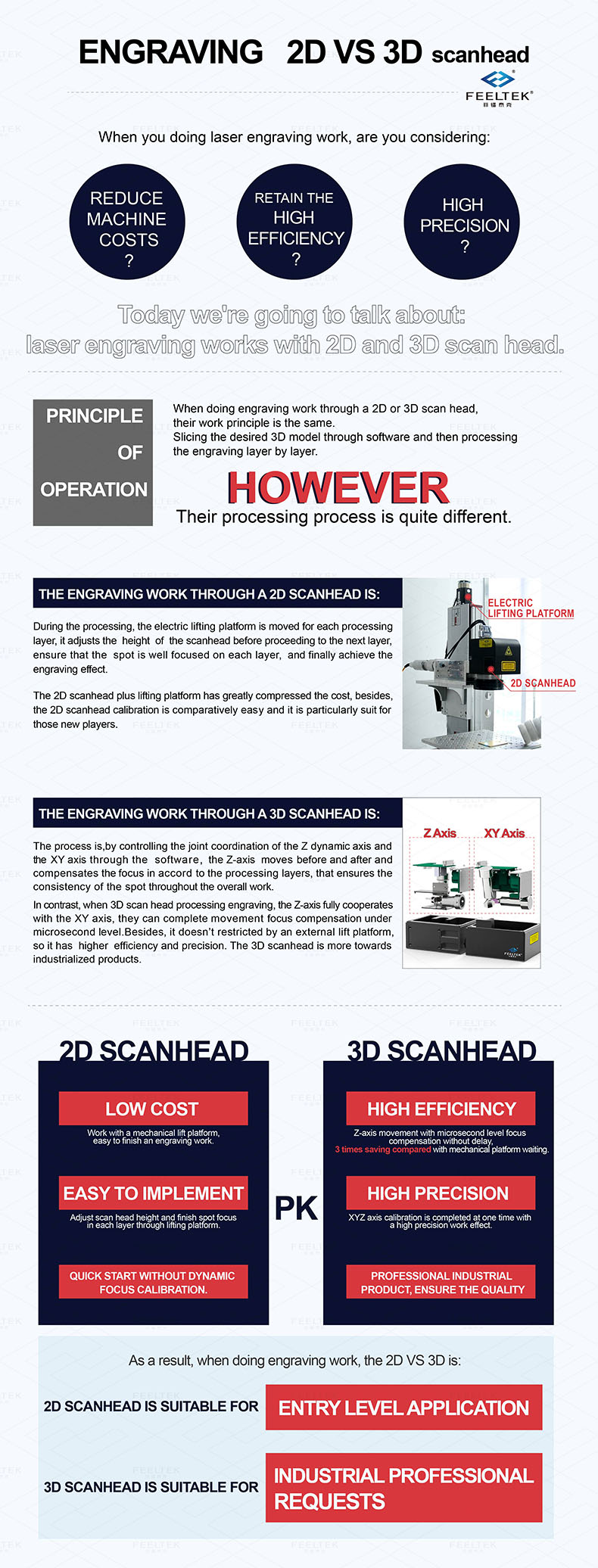

When you doing laser engraving work, are you considering:

Reduce machine costs?

Retain the high efficiency and high precision?

Today we’re going to talk about: laser engraving works with 2D and 3D scan head.

When doing engraving work through a 2D or 3D scan head, their work principle is the same. Slicing the desired 3D model through software and then processing the engraving layer by layer.

However, their processing process is quite different.

The engraving work through a 2D scan head is:

During the processing, the electric lifting platform is moved for each processing layer, it adjusts the height of the scan head before proceeding to the next layer, ensure that the spot is well focused on each layer, and finally achieve the engraving effect.

The 2D scan head plus lifting platform has greatly compressed the cost, besides, the 2D scan head calibration is comparatively easy and it is particularly suit for those new players.

As for a 3D scan head on its engraving work,

The process is, by controlling the joint coordination of the Z dynamic axis and the XY axis through the software, the Z-axis moves before and after and compensates the focus in accord to the processing layers, that ensures the consistency of the spot throughout the overall work.

In contrast, when 3D scan head processing engraving, the Z-axis fully cooperates with the XY axis, they can complete movement focus compensation under microsecond level.

Besides, it doesn’t restricted by an external lift platform, so it has higher efficiency and precision. The 3D scan head is more towards industrialized products.

As a result, the difference between 2D and 3D scan head doing engraving work is:

2D scanhead:

1. low cost, work with a mechanical lift platform, easy to finish an engraving work.

2. easy to implement, adjust scan head height and finish spot focus in each layer through lifting platform

3. quick start without dynamic focus calibration.

4. 2D scan head is suitable for entry level player

3D scanhead:

1. high efficiency. Z-axis movement with microsecond level focus compensation without delay, 3 times saving compared with mechanical platform waiting.

2. XYZ axis calibration is completed at one time with a high precision work effect.

3. professional industrial product, ensure the quality

4. 3D scan head is suitable for industrial professional requests.

Post time: Sep-15-2021